PRODUCT

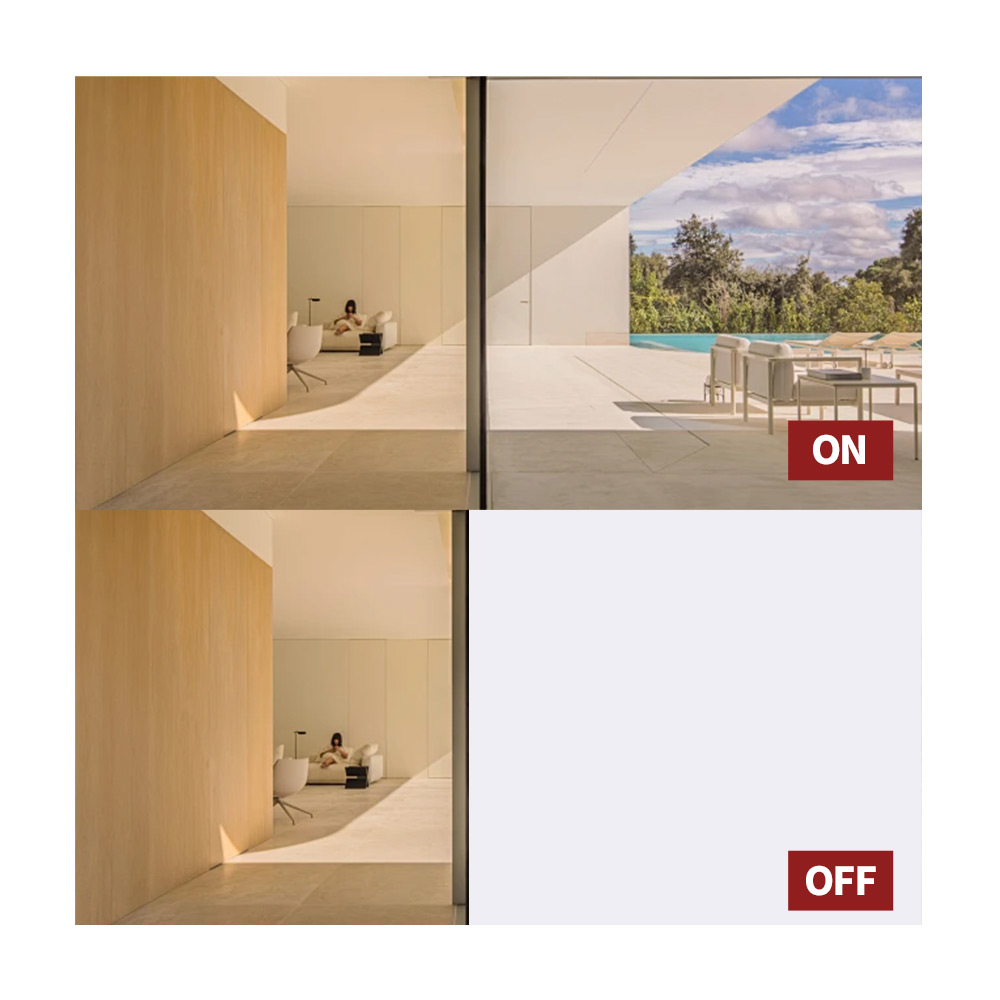

switchable smart glass film

Brand Name: HOMEWELL

Product Name: Smart Film Switchable

Technique:Clear Glass, Tempered Glass, Smart Glass

Material:PDLC

Feature:self-adhesive

Thickness:0.44mm

Standard width:≤14cm/14-18cm

Working voltage:AC48V~65V/50Hz

Power consumption:≤5W/㎡

Lifetime:>80000h

| Brand | Homewell |

| Material | PDLC |

| Feature | self-adhesive |

| Function | privacy protection,heat insulation,explosion proof,decorative |

| Thickness | 0.45mm |

| Standard width | ≤14cm/14-18cm |

| Length | customize |

| Working voltage | AC48V~65V/50Hz |

| Power consumption | ≤5W/㎡ |

| Lifetime | >80000h |

A high level of safety. When damaged by external forces, it only causes cracks, but it does not break. There is no risk of splashing glass fragments. They enter the interface between the liquid crystal ball and the polymer, because ne is not the same ne. So dispersion occurs and the STG is atomized. The appropriate penetration rate of visible light has a certain degree of concealment from strong outdoor light.sky:

**Introduction**

The Ipnorama of modern architecture and interior design, the search for intelligent, sustainable and adaptable solutions has led to the emergence of innovative technologies capable of radically changing the spaces in which we live and work. In this way, **pellicola PDLC (Polymer Dispersed Liquid Crystal)** represents one of the most important revolutions in the field of glass surface treatment. This electroactive film, thin and transparent, gives any window the ability to change its optical properties instantly, going from a perfectly transparent state to an opaque and diffusive state, guaranteeing privacy and dynamic solar control with a simple electrical command. PDLC technology is not a simple aesthetic novelty; It is an integrated solution that responds to the fundamental needs of living comfort, energy efficiency, environmental protection and functional flexibility. Questo approfondimento esplora la scienza, i mechanimi operativi, i vantagei, le appliqués potenciales, le specifica tecnique e le prospective future di questa extraordinary innovation, posizionandola come un pilastero del glass intelligente per gli edifici del presente del futuro.

. Scientific basis and operating principles**

The core of PDLC technology lies in the interaction between light and matter at the microscopic level, exploiting the unique properties of liquid crystals. The film is a multilayer sandwich of extreme engineering precision:

* **Central Functional Layer:** This is the active core. Consists of a transparent polymer matrix (typically a thermoplastic or photopolymerizable polymer) within which are dispersed microscopic droplets (typically 1-10 microns in diameter) of nematic liquid crystals. These liquid crystals have an optically anisotropic property, so that their interaction with light depends strongly on the orientation of the elongated molecules (calamite).

* **Transparent Conductive Layers (Electrodes):** Adjacent to the functional layer are two very thin layers of transparent conductive material, almost always made of ITO (Indium Tin Oxide). These layers act as electrodes.

* **Support Layers/Barriers:** The outer layers are usually made of PET (polyethylene terephthalate) with high resistance and transparency. These layers provide mechanical stability, protect the inner layers from moisture, oxygen and physical damage, and are often integral adhesives for application to glass.